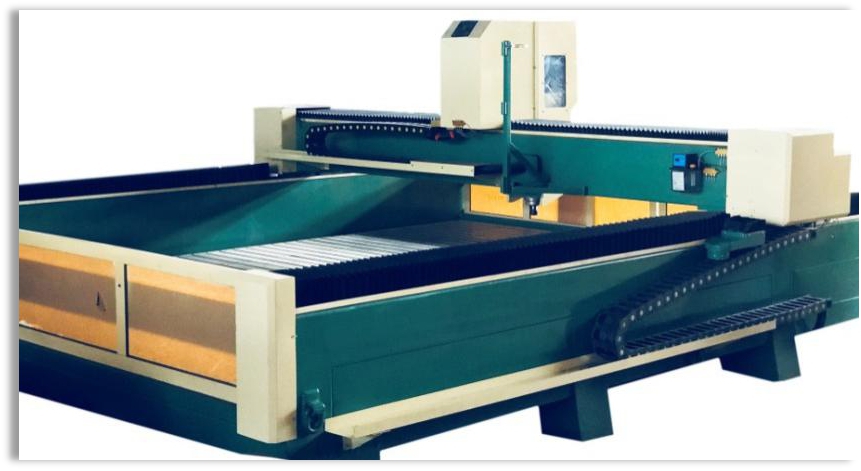

Transformer rwb thaiv tsev qhov chaw ua haujlwmlos ntawm kev teeb tsa qhov kev pab cuam, daim duab ntawm ib qho kev muab cov duab tuaj yeem txiav tawm ntawm cov ntoo laminated lossis laminated cardboard.Nws kuj tseem tuaj yeem ua cov voj voos thiab cov kab tawm ntawm lub nplhaib kawg, laum qhov thiab lub dav hlau hauv zos machining.Qhov tshwj xeeb yuav tsum tau ntawm transformer Kev lag luam rwb thaiv tsev yuav tsum tau txiav txim siab tag nrho hauv kev tsim thiab tsim khoom ntawm cov khoom siv no, thiab kev tiv thaiv tshwj xeeb yuav tsum tau ua hauv desusting thiab tiv thaiv cov pa phem hlau.

Technical parameter rau Transformer rwb thaiv tsev qhov chaw ua haujlwm

| Kev mob stroke (mm) Kev mob stroke (mm) | 1500 * 3000 hli | 3300 * 3300 hli |

| Qhov siab tshaj plaws machining Thickness (mm) | 150 | 260 |

| XY mus rau qhov ceev tshaj plaws khoob kab ceev (m / min) | 12 | 20 |

| XY mus rau qhov ceev tshaj plaws khoob kab ceev (m / min) XY mus rau qhov ceev tshaj plaws khoob kab ceev (m / min) XY mus rau qhov ceev tshaj plaws khoob kab ceev (m / min) | 3 | 8 |

| XY kev taw qhia qhov tseeb (mm) XY kev taw qhia qhov tseeb (mm) | 0.2 | 0.2 |

| Z-kev taw qhia qhov tseeb (mm) | 0.05 Nws | 0.05 Nws |

| Spindle ceev r/min | 0-24 000 Nws | 0 ~ 18000 |

| Spindle zog KW | 6 | 11 |

| Chaw ua haujlwm | Aluminium alloy T-slot los yog nqus adsorption | Aluminium alloy T-slot los yog nqus adsorption |

Peb yog 5A Class Transformer Tsev nrog kev daws teeb meem tag nrho rau Transformer Kev Lag Luam

A1, Peb yog cov chaw tsim khoom tiag tiag nrog cov chaw ua tiav hauv tsev

A2, Peb muaj ib tug kws R & D Center, muaj kev koom tes nrog zoo-paub Shandong University

A3, Peb muaj Cov Ntawv Pov Thawj Ua Haujlwm Zoo Tshaj Plaws nrog Cov Qauv Thoob Ntiaj Teb nyiam ISO, CE, SGS, BV

A4, Peb yog tus nqi zoo dua thiab tus neeg muag khoom yooj yim nruab nrog cov khoom lag luam thoob ntiaj teb xws li Simens, Schneider, thiab lwm yam.

A5, Peb yog ib tus khub lag luam txhim khu kev qha, ua haujlwm rau ABB, TBEA, PEL, ALFANAR, thiab lwm yam hauv 17 xyoo dhau los

Q1: Yuav ua li cas peb tuaj yeem xaiv cov qauv ntawv ci winding tshuab?

A: Thov muab koj cov ntsiab lus coil loj, cov khoom loj, cov kev cai tshwj xeeb, Peb tus engineer yuav ua tiav cov qauv tsim nyog rau koj.

Q2: Koj puas tuaj yeem muab cov kev pabcuam tig qhov tseem ceeb ntawm kev muab cov tshuab ua tiav thiab cov khoom siv rau lub Hoobkas tshiab transformer?

A: Yog, peb muaj kev paub nplua nuj los tsim lub Hoobkas tshiab transformer. Thiab tau ua tiav pab Pakistan thiab Bangladesh cov neeg siv khoom los tsim lub Hoobkas hloov pauv.

Q3: Koj puas tuaj yeem muab kev pab cuam tom qab muag thiab commissioning hauv peb qhov chaw?

Yog lawm, peb muaj pab pawg tshaj lij rau kev pab cuam tom qab muag. Peb yuav muab phau ntawv qhia kev teeb tsa thiab yees duab thaum lub tshuab xa khoom, Yog tias koj xav tau, peb tuaj yeem xa cov engineers tuaj xyuas koj qhov chaw rau kev teeb tsa thiab commission. Peb cog lus tias peb yuav muab 24 teev ntawm kev tawm tswv yim online thaum koj xav tau kev pab.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com