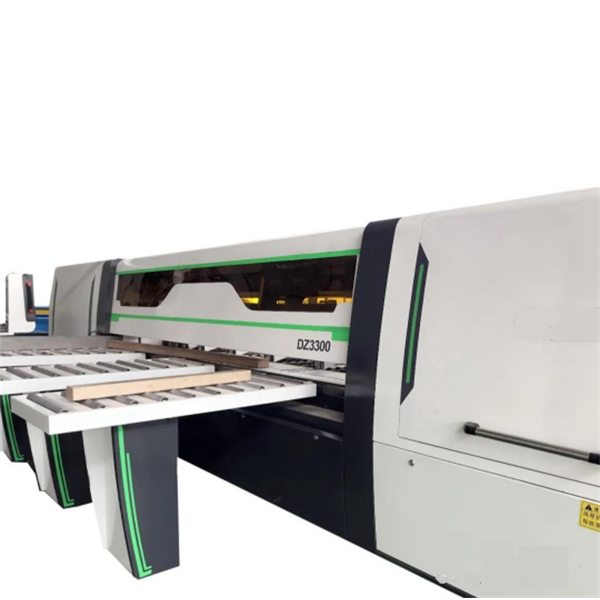

Tuam Tshoj OEM Transformer Roj Degasifier - Tag nrho tsis siv neeg winding spacer nqos tail dovetail milling tshuab - Trihope Detail:

Product details:

Lub Cim Tseem Ceebntawmspacer punching tshuab

Programming system yog yooj yim thiab yooj yim to taub

Intuitive txiv neej-tshuab interface programming, yooj yim rau siv

Built-in thaiv cov tsev qiv ntawv, yooj yim hu sai

Real-time xyuas qhov system

Block processing program tuaj yeem khaws cia rau hauv lub cim xeeb tswj

adopts plaub high-speed motorized spindle li milling taub hau, tshuab tsim compact, luv luv ua hauj lwm rooj stroke ua rau kev kub ceev machining efficiency.

Spacer milling tshuab txais cov qauv tsim, peripherals pob tshab hom ntaub thaiv npog, cov khoom siv suab nrov sab hauv, nqus lub qhov ncauj txuas nrog lwm cov plua plav catcher.Qhov inlet thiab qhov hluav taws xob yog tsim los tiv thaiv plua plav, uas tuaj yeem tswj tau cov dej ntws ntawm cov plua plav thiab suab nrov thaum lub sij hawm milling. , thiab tseem tiv thaiv ib puag ncig huv ntawm lub rhiav insulating.

Dhau li ntawm cov ntaub thaiv npog ntawm lub tshuab spacer milling yog ua los ntawm 2 hli tuab steel phaj thiab toughened iav thiab hluav taws xob sib cuam tshuam, thaum lub tshuab pib, tuaj yeem nres txhua yam kev puas tsuaj tsis zoo thiab tus kheej, txhim kho kev nyab xeeb.

Main technical parameter rau lubspacer milling tshuab

Kev ua ntau yam:

Block ntev: 25 ~ 300 hli

Block dav: 25 ~ 60 hli

Pad thickness ua ntau yam: qhov siab tshaj plaws 350 hli

Pom lub taub hau ceev: 3000 r / min.

Pom lub taub hau txav ceev: 2 ~ 5 m / min

Arc rau ceev: 9000 ~ 24000 n / min;

Qhov riam ceev: 9000 ~ 24000 n / min;

Machining precision thaiv qhov ntev: cov khoom siv ua txhua yam ntawm precision thaiv qhov ntev yuav tsum ua tau raws li + / - 0.2 hli

Machining qhov tseeb ntawm qhov zawj ntawm qhov thaiv: thaiv cov cuab yeej ua tiav txhua hom kev ua tiav dovetail, nquab tus Tsov tus tw, ncaj zawj qhov tob yuav tsum ua tau raws li + / - 0.2 hli, cov cuab yeej yuav tsum xyuas kom meej tias kev ua tiav ntawm qhov ntev thiab sab nraud ntawm ob qhov thaiv cov khoom kev taw qhia compaction, compaction, machining txheej txheem thaiv cov khoom yuav tsum ntsug thiab mesa tsis qaij, kom ntseeg tau tias kev ua ntawm ntau hom rabbet chaw nruab nrog cov ntaub qhwv ntaub sib tshooj, sib txawv yuav tsum

yog +/- 0.15 mm.

Spacer milling tshuab lub cev steel cov tswv cuab rau kev laus kev kho mob, qhov tseem ceeb kis tau tus mob yuav tsum ua raws li kev kho cua sov.

Lub cev muaj peev xwm ntsia tau: txog 16 kw (tsis suav nrog lub tshuab nqus plua plav)

Spacer milling tshuab hnyav: 3.5 tons;

Pneumatic system siab thiab ntws tus nqi: 0.6 MPa thiab 0.2 m3 / min

Tshuab Video

5A Solution Provider

Peb yog 5A Class Transformer Tsev nrog kev daws teeb meem tag nrho rau Transformer Kev Lag Luam

A1, Peb yog cov chaw tsim khoom tiag tiag nrog cov chaw ua tiav hauv tsev

A2, Peb muaj ib tug kws R & D Center, muaj kev koom tes nrog zoo-paub Shandong University

A3, Peb muaj Cov Ntawv Pov Thawj Ua Haujlwm Zoo Tshaj Plaws nrog Cov Qauv Thoob Ntiaj Teb nyiam ISO, CE, SGS, BV

A4, Peb yog tus nqi zoo dua thiab tus neeg muag khoom yooj yim nruab nrog cov khoom lag luam thoob ntiaj teb xws li Simens, Schneider, thiab lwm yam.

A5, Peb yog ib tus khub lag luam txhim khu kev qha, ua haujlwm rau ABB, TBEA, PEL, ALFANAR, thiab lwm yam hauv 17 xyoo dhau los

FAQ

Q1: Yuav ua li cas peb tuaj yeem xaiv cov qauv ntawv ci winding tshuab?

A: Thov muab koj cov ntsiab lus coil loj, cov khoom loj, cov kev cai tshwj xeeb, Peb tus engineer yuav ua tiav cov qauv tsim nyog rau koj.

Q2: Koj puas tuaj yeem muab cov kev pabcuam tig qhov tseem ceeb ntawm kev muab cov tshuab ua tiav thiab cov khoom siv rau lub Hoobkas tshiab transformer?

A: Yog, peb muaj kev paub nplua nuj los tsim lub Hoobkas tshiab transformer. Thiab tau ua tiav pab Pakistan thiab Bangladesh cov neeg siv khoom los tsim lub Hoobkas hloov pauv.

Q3: Koj puas tuaj yeem muab kev pab cuam tom qab muag thiab commissioning hauv peb qhov chaw?

Yog lawm, peb muaj pab pawg tshaj lij rau kev pab cuam tom qab muag. Peb yuav muab phau ntawv qhia kev teeb tsa thiab yees duab thaum lub tshuab xa khoom, Yog tias koj xav tau, peb tuaj yeem xa cov engineers tuaj xyuas koj qhov chaw rau kev teeb tsa thiab commission. Peb cog lus tias peb yuav muab 24 teev kev tawm tswv yim online thaum koj xav tau kev pab.

Product details duab:

Yam khoom Guide:

Tuam Tshoj OEM Transformer Roj Degasifier - Tag nrho tsis siv neeg winding spacer nqos tail dovetail milling tshuab - Trihope, Cov khoom yuav muab rau thoob plaws lub ntiaj teb no, xws li: , , ,

Los ntawm -

Los ntawm -  Los ntawm -

Los ntawm -  +8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com