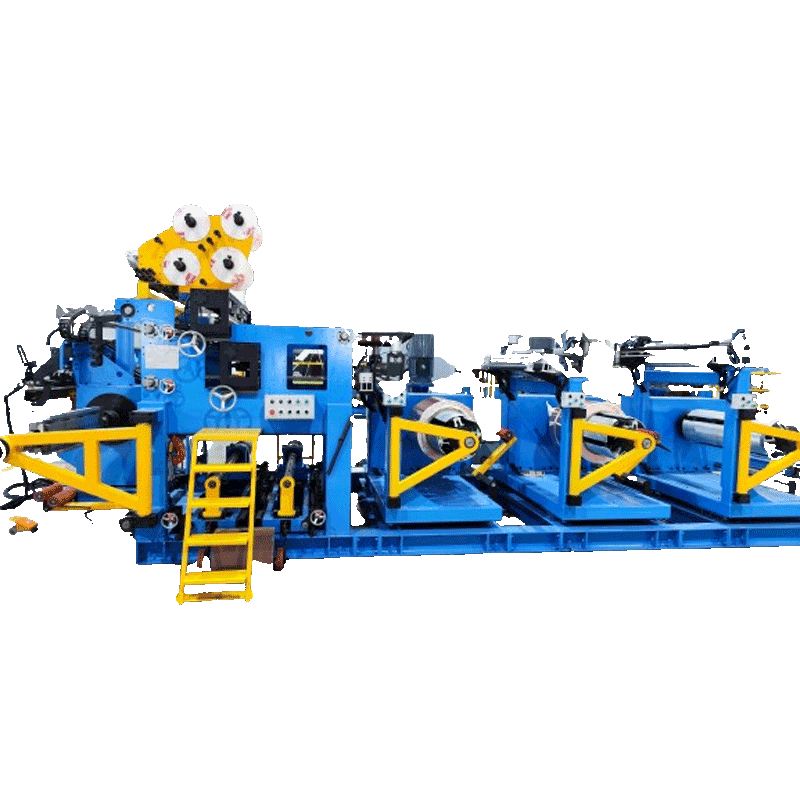

Kuv.Cov ntsiab lus

LV foil coil siv cov thickness tooj liab los yog txhuas ntawv ci raws li tus neeg xyuas pib, cov khoom siv dav hauv cov khoom siv rwb thaiv tsev zoo li txheej rwb thaiv tsev, ua tiav winding hauv cov ntawv ci hom winding tshuab, sib sau yob coil.

Cov khoom siv no kuj tuaj yeem siv rau cov coil winding zoo sib xws ntawm kev lag luam hluav taws xob.

Lub tshuab txais PLC tswj txoj kev nrog cov yam ntxwv ntawm qib siab ntawm automation.

Ⅱ.Kev sib xyaw thiab kev ua haujlwm ntawm cov khoom siv

BR/III-1100 Peb-Layer Ntawv Nyiaj Winding Tshuab suav nrog

1) Cov ntaub ntawv de-coiling ntaus ntawv 2) Winding device 3) Txheej rwb thaiv tsev decoiling ntaus ntawv

4) Lub ntsiab ncej 5) Vuam ntaus ntawv 6) Deburring thiab tu ntaus ntawv

7) Cov cuab yeej txiav 8) Qhov kawg rwb thaiv tsev uncoiling ntaus ntawv thiab lwm yam

III. Main Technical Parameters

| Sr# | Yam khoom | SPECIFICATION |

| 1 | Coil | Kev ua ntau yam |

| 1.1 | Axial ntev | 250 ~ 1100 hli |

| 1.2 | Axial ntev (xws li txhuas) | 400 ~ 1760 hli (nrog cov hlau lead RH 16 nti, LH 10 nti) |

| 1.3 | Sab nraud txoj kab uas hla (Max) | Φ1000 Nws |

| 1.4 | Coil daim ntawv | Round / cylindrical / rectangular / coil hnyav ≤2000KG |

| 1.5 | Center qhov siab | 8 50mm |

| 2 | Coil Khoom | Copper foil, aluminium ntawv ci |

| 2.1 | Dav | 250-1100 hli |

| 2.2 | Thickness (Max) (tag nrho thickness) | Copper foil: 0.3 ~ 2.5 hli Aluminium ntawv: 0.4 ~ 3mm |

| 2.3 | Coil sab hauv txoj kab uas hla | Φ400-500mm |

| 2.4 | Coil sab nraud txoj kab uas hla (Max) | φ1000 hli |

| De-coiler | Kev ywj pheej peb teev |

| 3.1 | Ntev ntawm cov kabmob cylinder | 1150 hli |

| 3.2 | Expansion ntau ntawm bearing cylinder | Φ380~φ520 |

| 3.3 | Bearing muaj peev xwm (Max) | 2000 KG |

| 3.4 | Expansion quab yuam (Hluav taws xob) | 0 ~ 15000N Expansion force stepless adjustable |

| 3.5 | Hom kev kho offset | Manual/Automatic |

| Winding tshuab |

|

| 4.1 | Cua ceev | 0-20 rpm |

| 4.2 | Ua haujlwm torque (Max) | ≥8000N·M |

| 4.3 | Cua zog | 20-30 KW |

| 4.4 | Txoj kev tswj ceev | Zaus conversion stepless ceev tswj |

| 4.5 | Winding ncej | 50 * 90mm |

| 5 | Vuam ntaus ntawv |

|

| 5.1 | Vuam hom | TIG |

| 5.2 | Ua bar vuam thickness | ≤ 20mm |

| 5.3 | Vuam ceev | Nws pib ceev tswj 0 ~ 1m / min Stepless ceev tswj |

| 6 | Cov cuab yeej txiav |

|

| 6.1 | Txiav daim ntawv | Lead Screw Txiav Disc |

| 6.2 | Txiav ceev | 1.5m / min |

| 6.3 | Txiav ntev | 1150 hli |

| 7. | Txheej insulatinguncoilntaus ntawv | |

| 7.1 | Txheej rwb thaiv tsev ntsia tau ncej | 2set ib |

| 7.2 | Txheej rwb thaiv tsev yob txheej txoj kab uas hla | ≤φ400 hli |

| 7.3 | Txheej rwb thaiv tsev yob puab txoj kab uas hla | φ76 hli |

| 7.4 ib | Txheej rwb thaiv tsev yob dav | 250-1150 hli |

| 7.5 | De-coil ncej nro txoj kev | Pneumatic hom |

| 8. | Covkawginsulation uncoiling ntaus ntawv |

|

| 8.1 | Ntau | Sab laug thiab sab xis txhua 4 teev |

| 8.2 | Qhov kawg rwb thaiv tsev sab nraud txoj kab uas hla | ≤φ350 hli |

| 8.3 | Qhov kawg rwb thaiv tsev iner diameter | Φ56 hli |

| 8.4 | Qhov kawg rwb thaiv tsev dav | 10-100 hli |

| 9. | Rectifying ntaus ntawv (foil alignment) | Kuvnce 3sets |

| 9.1 | Rectifying hom | Photoelectric system |

| 9.2 ib | Rectifying precision | Random ± 0.4 hli 20 txheej coil ± 1mm |

| 10. | Hluav taws xob tswj qhov system | PLC tsis siv neeg tswj hom |

| 10.1 | Tus lej ntawm cov digitals | 4-digital (0–9999.9) suav qhov tseeb 0.1 tig |

| 10.2 | Kev ua haujlwm interface | Xim kov npo |

| 11. | Lwm yam |

|

| 11.1 | Txheej rwb thaiv tsev tej cuab yeej | Configuration ob txheej |

| 11.2 | Foil khoom ntug deburring ntaus ntawv | Configuration peb poob lawm |

| 11.3 | Foil khoom siv ntxuav | Configuration peb poob lawm |

| 11.4 | Vuam dej txias tank | kev teeb tsa |

| 11.5 | Fais fab mov | 3-PH,380V / 50HZ (tuaj yeem kho tau) |

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com